#Screw

gauges tools

shared a few photos

Nancy Liu

posted a blog.

December 15, 2019

118 views

There are many types of automatic electric screwdrivers. The specific use sometimes requires special accessories to adapt to the relevant work. The following describes several common special accessories and functions.

1 #Press the self-start function

The appearance of the electric screwdriver does not have the trigger of the power switch. The pushrod is driven by the axial movement of the lower slot or the cross slot of the screwdriver head. And the jack passes through the center hole of the clutch, the center gap of the reducer, and the shaft hole of the hollow rotor shaft, then can start the screwdriver. A power switch installed at the rear end of the motor starts the motor. It can reduce the action of the operator pressing the trigger, simplify the operation, improve work efficiency and reduce the labor intensity. When it equips an adjustable precision power-off clutch, some domestic users call it an "full-automatic electric screwdrivers". While the electric screwdriver with only automatic power-off type, it calls a "semi-automatic electric screwdriver".

2 #Screw adsorption function

One is a magnetic screwdriver head: use magnetic to make screwdriver head attract with the screw head for easy installation, it is suitable for ferromagnetic screws.

The other is a vacuum screw adsorber: use a vacuum pump to suck the screw head by causing a negative pressure in the suction cover of the screwdriver head through a plastic suction pipe. This accessory is suitable for small sizes of various material screws. The purpose of increasing the screw adsorption function is to reduce labor intensity.

3 #Right angle drive head

Turn the output shaft a 90° for a particularly narrow workpiece assembly space.

4 #The stock

Convert straight-type tools into pistol-type tools to accommodate horizontal thread assembly work. At the same time, the force arm of the handle is longer, which can withstand large reaction torque. When it id using on the large electric screwdriver to reduce labor intensity.

5 #Anti-torque bracket

From the perspective of human physiological and mechanical aspects, the Chinese Co-share brand has developed a counter-torque bracket for electric screws with large torque. One end is fixed on the electric screwdriver. The other end forms a groove adapted to the forearm of the human hand so that the counter-torque of the screwdriver acts on the longer force arm to reduce the labor intensity of the operator.

6 #Balancer

Hang the attachment using an electric screwdriver. It allows the tool to be freely balanced to any height with the operator's intent. In addition to reducing labor intensity, there are still unsafe factors that make the workplace tidy and reduce accidental injuries.

Conclusion:Â The selection of an electric screwdriver also depends on the workplace and the conditions of use. Please refer to this article for the specific type:Â How to Select Household and Industrial Electric Screwdrivers

Be the first person to like this.

Precision Bearing House

shared a photo

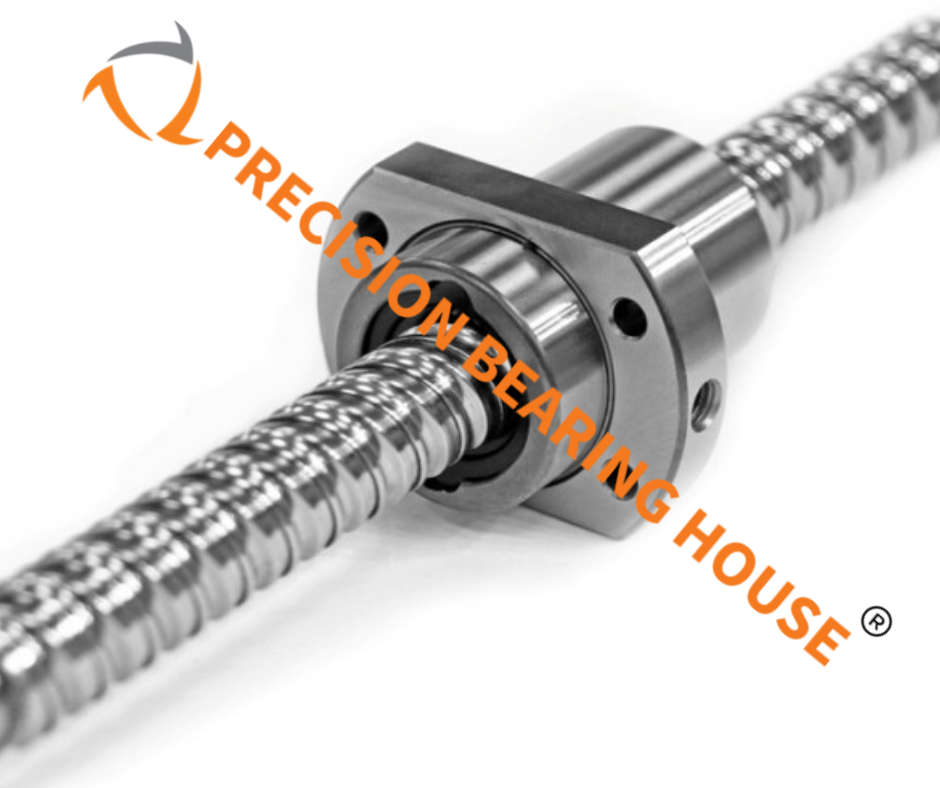

Precision Bearing House Providing a best product one of them is #Rolled #Ball #Screw FSU 6310- C7 Rolled Ball Screw with Nut Diameter 63 mm Pitch 10 mm

Click here to Buy #BallScrew: https://bit.ly/2J... View More

Be the first person to like this.

Precision Bearing House

shared a photo

Precision Bearing House Providing a best product one of them is #Rolled #Ball #Screw FSE 2020 with Nut Diameter 20mm, Lead 20mm

Click here to Buy #BallScrew: https://bit.ly/2VGAGF8

Reach Us... View More

Be the first person to like this.