He is the owner/CEO of Storify News. Forbes calls him a top influencer of Chief Marketing Officers a... View More

About Me

Movies

Pearl harbour

Music

Linkin parkMaroon 5Katy Perry

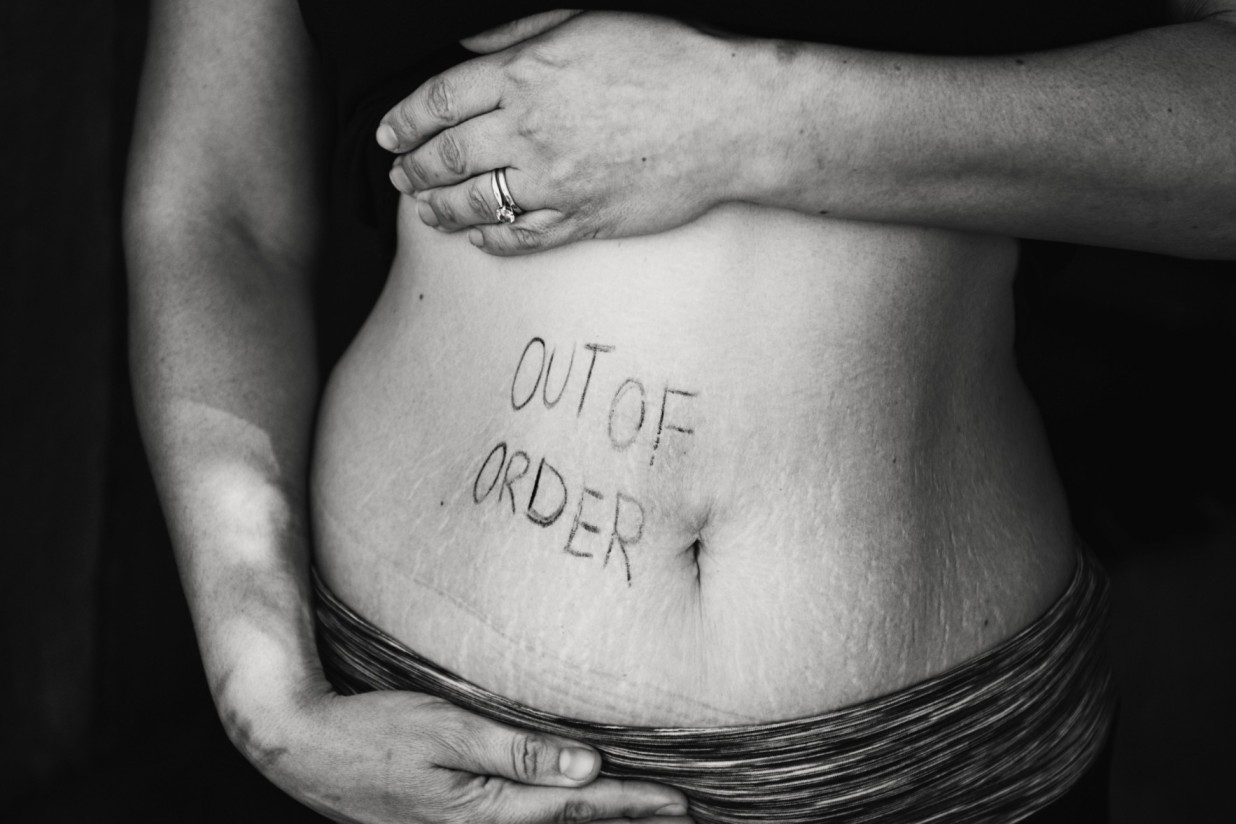

Top 10 Classy Stomach Tattoos for Women in 2023

One of the top 10 classy stomach tattoos for women in 2023 are butterflies. Butterflies are often a sign of growth, and they signify that one is entering a new chapter.

Be the first person to like this.

The 7 Best Hybrid Pickup Trucks You Can Buy Right Now | Storify News

A hybrid pickup truck is a vehicle that combines a gasoline engine with an electric motor or another power source to improve fuel efficiency and reduce

Be the first person to like this.

OnlyFans Content on ThotsBay: Is it Legit?

ThotsBay offers free downloads of your favorite camgirls and pornstars, letting you enjoy full HD videos from some of the hottest women on Earth with no threat of viruses or malware, privacy invasion,

Be the first person to like this.

Erric Ravi

posted a blog.

Have you ever wondered how bomb-detecting robotic vehicles are controlled or how a metal cutting and forming machine offers highly precise motions for milling and bending?

To achieve any of this, having a suitable electric motor in the electromechanical system is imperative, especially when the system demands maximum precision. And when it comes to increasing precision and motor controls, you cannot neglect the star of this article, that is, servo motors.

Read along to learn about its functions and working mechanism and why they are the most commonly found devices in high precise motions.

What is a Servo Motor?

A self-contained electrical device, servo motors rotate parts of a machine with high efficiency and remarkable precision. It implies an error sensing feedback control that is employed to improve the system performance. It also requires a dedicated module designed especially for servo motors. They usually have a cycle cut off from 90- 180°. Some of them also own a revolution cutoff of 360° or more. But these devices do not rotate continually. Their rotation is restricted between fixed angles.

It enables you to move the output shaft to a particular angle, position and velocity that any other regular motor does not offer. It utilises a standard motor and couples it with a sensor for positional feedback.

A servo motor is an assembly of four elements:

A normal DC motor

A gear reduction unit

A position-sensing device

A control circuit

The DC motor is combined with the gear unit to provide feedback to the position sensor, mostly a potentiometer. The motor output is delivered through a servo spline to the servo arm from the gearbox.

Advantages:

In heavy loading, the driver increases the current to the motor coil as it strives to rotate the motor. No out-of-step condition exists.

High-speed operation is possible.

Disadvantages:

It is not appropriate for precision control of rotation as it rotates according to the command pulse but experiences lag.

It involves higher costs.

It is not suitable to prevent vibrations as the motor's rotor moves back and forth one pulse even after stopping it.

How does a Servo Motor work?

A servo motor comprises three wires - a black wire is connected to the ground, a white or yellow wire is connected to the control unit, and a red wire is connected to the power supply.

The fundamental function of the servo motor is to take a control signal that describes a required output position of the shaft and apply power to the DC motor until the shaft turns to the desired position. This position-sensing device helps figure out the shaft's rotational position to know the right direction to turn the motor in to move the shaft to the instructed position. Unlike a DC motor, the shaft does not rotate freely but can turn only 200 degrees.

A rotating magnetic field is generated from the rotor's position by the current flowing in the winding to create the toque efficiently. The shaft conveys the motor output power, driving the load via the transfer mechanism. A High-function rare earth magnet or any other permanent magnet is then positioned outside the shaft.

What are the applications of Servo Motors?

Servo motors are used in:

packaging, machine tools, factory automation, printing converting, material handling, assembly lines, and many other critical applications like CNC machinery, robotics, or automated manufacturing.

Radio-controlled aeroplanes to control the positioning and movement of elevators.

The aerospace business to maintain hydraulic fluid

Many radio-controlled toys.

Electronic devices like Blu-ray Disc players or DVD players to extend or replay the disc trays.

Automobiles to keep the vehicle speed.

Schneider Electric India is an expert in this industry, explore more products in industrial automation like distance relay, servo motors.

Erric Ravi

posted a blog.

Industrial automation is hailed as the next phase of the industrial revolution. A plethora of companies have either already adopted industrial automation or are in the process of doing so. It refers to using control systems and information technology like computers or robots, with an aim to reduce and replace human intervention in industrial processes. These industrial processes pertain to different roles like controlling, sensing, supervision, and monitoring. Industrial automation has many benefits. It helps substantially cut or, in some cases, even eliminate labour costs. It reduces error margins and uses the latest technology to ensure adequate quality control. Industrial automation is widely prevalent and is used to optimize overall performance.

What is SCADA?

Supervisory Control and Data Automation (SCADA) is a comprehensive automated control system composed of both hardware and software components that work together to supervise different industrial procedures. Apart from this, through SCADA systems, it is possible to record and analyze real-time data. Data collected through various channels is then presented to the user for them to take appropriate control decisions. SCADA systems work locally as well as remotely. These systems are widely used in industries like oil and gas, chemicals, power and energy, and food and beverages, among others.

Two crucial elements of SCADA are:

• PLC (Programmable Logic Control)

• HMI (Human- Machine Interface)

Programmable Logic Control (PLC)

Programmable logic controllers (PLCs) is a type of industrial computer which is used to oversee and debug different machines and objects. PLC chiefly consists of 4 components which are:

• CPU (Central Processing Unit)

• Input module

• Output module

• PLC software

In the initial stage, PLCs receive input data from sensors and machines implanted in the physical factory floor through the CPU, which acts as the brain of PLC. This data can include on/off states, pressure levels, liquid levels, temperatures, etc. In the next stage, PLC outputs directions according to its pre-programmed protocols. This can directly command machines to turn on/off. PLCs operate and make control decisions on the basis of pre-installed PLC software. Reworking PLCs does not require any hardware changes; it can easily be achieved by rewriting the software code. Traffic lights are a popular example of PLCs.

Human-Machine Interface (HMI)

A human-machine interface is a network between the machine and the operator. It is essentially a device that displays a machine’s real-time operational information to give the operator insight. HMI collects data from PLCs and other control level systems like RTUs (Remote terminal Unit) or supervisory level systems like SCADA. It then converts complex machine variables into easily understandable information which the users see. HMIs come in the form of devices like screens, buttons, keyboards, touch screen tablets, etc.

How do SCADA, HMI, and PLCs Work Together?

SCADA works as the central control system that oversees other subsystems. SCADA communicates with PLC and obtains real-time information about machine functioning. This information, once decrypted, is then displayed on HMIs for the operator’s perusal. Through this, SCADA regulates and directs various equipment operations and can even dispatch emergency protocols. Thus PLC, SCADA, and HMI work together to ensure effortless automation and functioning of industrial procedures. Industrial automation technology is dynamic and a necessity in today’s world. Schneider Electric is among the top companies producing premium HMI, PLC, and SCADA systems, using high-grade and advanced technology. Visit the #SchneiderElectricIndia website today!

Be the first person to like this.

Erric Ravi

posted a blog.

With the changing times, electrical switches are gaining a lot of attention. Modular switches are the latest, stylish switches that are at par with the traditional ones. Unlike conventional switches, these switches are convenient, safe and easy to use. These switches consist of a few essential parts, which includes the concealed boxes, modular plate and switch or plug module. Each household has a unique combination of requirements in terms of switches. The use of old conventional switches has now been limited, and people have shifted to aesthetically pleasing smart switches that are safe.

Modular switches offer various advantages, which include:

Elegant Design

The modular switches are available in different design, style and colour to match the house's interior. These switches are also known as designer switches as they are stylish and appealing. You can opt for the following switches if you are renovating or constructing a new house:

Designer Switch Plates

Glass Switch Plates

Coloured Blocked Switch Plates

Operation Safety

People switch from conventional switches to modular switches because these switches provide operational safety. Traditional switches have exposed metal screws or wires, which increases the cause of the mishap. However, the modular switches do not come with any exposed parts, making them safe for everyone. These switches are crafted with high-quality material that does not contain any metal parts on its face. The modular switches are shuttered which makes them the best for children.

Multi-Functional

Since the modular switches can be installed anywhere, they are used for different purposes like automation, security and data transmission. These switches offer operational flexibility as they can be easily installed and removed. You can use it for heavy operational activities as well because these switches are available in many capacities.

Efficient

The internal wiring of modular switches is intended to be efficient to take the load. These switches are built under stringent quality control for endurance. To ensure soft touch and noiseless operation, these switches are designed.

Some of the latest features of these smart switches are:

These switches are best for home automation.

The modular switches have aesthetically pleasing designs.

The switches are well-sealed, solid and resistant to chemical changes.

The switches can also be controlled remotely.

It can be easily installed and removed.

Changeable light switches offer fashionable and classic experiences.

Anti Bacterial switches help to make switches and cover plates self-disinfectant.

Modular switches even have dimming control facilities.

Along with these, there are other features as well like hidden screws, anti-weld designs, smooth operations, shuttered electrical sockets etc. Modular switches are easy to assemble, install and use. Schneider Electric India helps to remodel your home by replacing the traditional switches with multipurpose Schneider's switches. Their switches are stylish and are designed to complement the design of the interior. They offer switches in different colours, types and with different power ratings. If you want to look out for the features like automation, security and data transmission, visit the #SchneiderElectricIndia website today!

3 people like this.

Erric Ravi

posted a blog.

The phenomenon of lightning is a harmful situation for not only physical structures in the form of buildings but human beings as well. Each thunderstorm has the capacity to destroy physical structure if it is not properly preserved and safeguarded from the possibility of lightning.

The condition of lightning can leave a devastating effect, while transients and surges caused by other circumstances can also result in similar destruction. Even though surges are extremely fast - in fact, they are calculated in nanoseconds, however, they can still result in significant destruction to electronic equipment. Apart from destroying wiring and data cables, electrical surges can also damage computer equipment, telephones and similar electronic goods, gradually wearing down the appliances internal elements. This is where the role of a surge arrester comes into the picture.

Any type of equipment can be subject to dynamic over-voltages, which can arise as a result of a lightning situation or a switching event. This develops a voltage spike enhancing the wave’s magnitude to potentially thousands of volts. This could result in rapid damage or significantly lower an equipment’s lifespan. A surge arrester can be explained as a voltage-activated surge protection appliance that protects computers and other electronic devices from surges or transient voltages in electrical power distribution systems or data cables. These commonly arise from a flash of lightning or a switching surge. Surge protection devices fundamentally redirect the excess voltage into the earth wire, instead of allowing it to relay through the electronic devices, while at the same time, enabling the normal voltage to flow along its original path.

The applicability of surge arresters is influenced by a wide array of unique factors. These can include the exposure of a building to voltage transients caused by lightning, the robustness or sensitivity of the equipment in question, the type of material used in the elements at the time of manufacturing, and lastly whether there is any unprecedented equipment inside the installation that could possibly produce voltage transients in the future.

Types of Surge Arresters -

Secondary Arresters - Secondary arresters are arresters that are rated under 1000 V. Secondary arresters are used to shield against secondary surges. Transformer failure rates range from 0.4-1%. 50-70% of all transformer failures occur due to low-side surges.

Distribution Arresters - Distribution arresters are 1 to 36 kV rated. Within the distribution type, there are light-duty, normal duty, and heavy-duty arresters. Heavy-duty arresters are also known as a riser pole arrester. Distribution arresters can also be implemented in transformers as under-oil arresters, cubicle-mounted arresters, and elbow arresters.

#SchneiderElectricIndia is one of the leading brands in the case of electrical protection equipment.

Be the first person to like this.

Erric Ravi

posted a blog.

So, here’s my list of questions which will help you decide if you need a Smart Home or not

You are working from home and are mostly on calls?

If yes, then a Smart Home with innovations such as home control and home automation is your ultimate savior. From switching off the squeaky fan to reducing its speed or switching on the extra light just before the video call to ensure you don’t look like a ghost in the darkroom. All this while sitting on the chair or on your bed with your headphones on! Yes, you don’t move but all you do is take your phone out and press a few buttons or simply ask Alexa to do it.

From spending hours in line to buy the iPhone or updating your Android to the latest version, if technology gives you a kick and you love to be at speed with it then a Smart Home is something you should get your hands on to. Flaunt it and it’ll never cease to surprise people.

Read Full Article here : https://blog.se.com/residential/2020/05/28/the-easiest-way-to-decide-if-you-need-a-smart-home/

Be the first person to like this.

Erric Ravi

posted a blog.

Power factor correction can turn out to be extremely favourable when it comes to your utility bill. Some of the advantages that come with it are reduced demand charges on your power system, which thereon increases the load carrying capabilities in your current circuits and overall reduces power system loss. To give you more clarity, below are some of the advantages regarding the potential financial impact PFC has on your utility bill.

1. Try to avoid Power Factor Penalties

Most of the industrial processing facilities that you see around yourself have gigantic induction motors that provide support to their conveyors, pumps, and other machinery in the plant. Due to these induction motors, it makes the power factor inherently low for most industrial facilities. All the electric utility companies consist of a power factor penalty for all the lower power factor (below than 0.80 or 0.85). Then there are high power factors (above 0.95, for instance). When you add power factor correction, then you have the opportunity to eliminate the power factor penalty from your bill.

2. Reduced Demand Charges

There are many electric utility companies that charge for maximum metered demand based on either the highest registered demand in kilowatts (KW meter) or bet on a percentage of the highest registered demand in KVA, whatever suits you. So in simpler terms, if the power factor is low, then the percentage of the measured KVA will also be significantly greater than the KW demand. So if you focus on improving the power factor through power factor correction, what it will do lower the demand charge which will then reduce your electricity bill.

3. Increased Load Carrying Capabilities In Existing Circuits

The load that extract reactive power also demands the reactive current. In order to reduce the current that is carried by every circuit breaker what you can do is instal power factor correction capacitors at the end of the existing circuits which are placed near the inductive loads. Once you reduce the current flow, it will improve the power factor, which might make way for the circuit to carry new loads, which will help you save cost on upgrading the distribution network. And, also save money that your company might have spent on unnecessary upgrade related costs.

4.Better and Efficient Voltage

So if you invest in lower power, it will create a higher current flow for a specific load. So when the line current increases, you will see the voltage drop in the conductor will increase, which therefore will result in a lower voltage at the equipment. Hence, with the help of an improved power factor, the voltage drop in the conductor is reduced and therefore improving the voltage in your equipment.

5. Reduced Power System Losses

If we are talking about the financial return that we get from conductor loss reduction alone, it is not sufficient enough to justify the installation of capacitors. At times, it acts as an attractive additional benefit, especially when it comes to older plants that consist of long feeders or in field pumping operations.

So these were some of the advantages that come with Power Factor correction and power management and its impact on your utility bill. If you want the same for your plant, a company that you can trust the company is #SchneiderElectric.

Be the first person to like this.