About Me

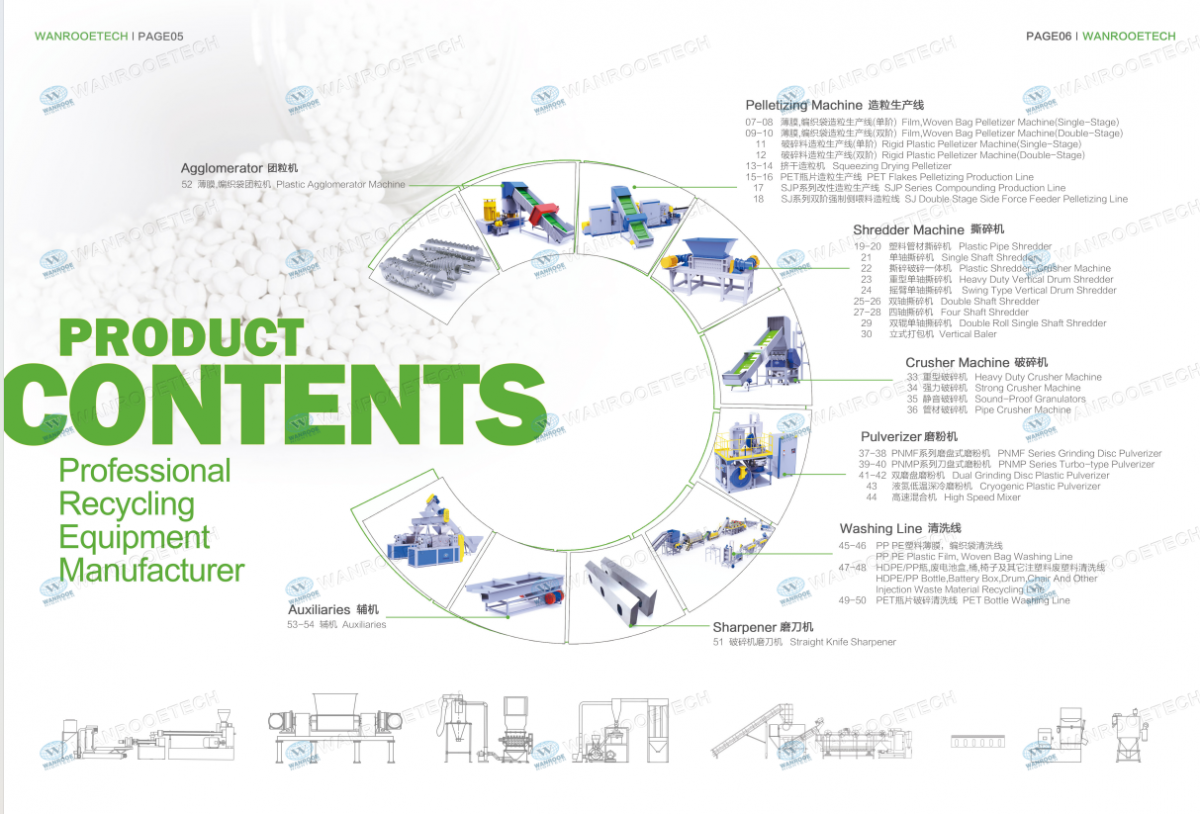

https://www.wanrooe.com/WANROOETECH is an ISO 9001:2008, CE-certified original manufacturer, exporte... View More

Who I'd Like to Meet

Movies

Interests

Friends

Video Player is loading.

PVC Washing Line PVC Crusher Machine Plastic Scrap Washing and Drying Machine

8 views

Technical Features: 1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 100-2000kg/hr. 2.Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop. 3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes. 4. This China Hot Selling Waste PVC Washing Machine can easily wash and recycle waste PVC materials. Equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed. 5. The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products. 6. Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PVC bottles to be the PVC granule material and in order to produce new PVC bottles.

Be the first person to like this.

Video Player is loading.

2000-3000kg/h Plastic Recycling Line PET Bottle PVC Profiles Pipes and Sheets Washing Line

7 views

2000-3000kg/h Plastic Recycling Line PET Bottle PVC Profiles Pipes and Sheets Washing Line

The washing line is suitable for PVC profiles, pipes, sheets, etc. At the same time, it can also be used for ABS, PS, PC and other materials that sink to the bottom of the water. This machine can also be used to clean PET bottles, the washing line need adds a hot washing machie, PET generally needs hot washing machine.

Description: The recycling plant takes dirty bottles and transforms them into clean material. And the profile can be further processed and reutilized with high commercial value. The production capacity we can make on the washing and recycling line can be 300kg/h to 3000kg/h. The line main purpose is intending to get the clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line. And also get clean PP/PE collection, labels and paper chips, etc. The device divided into unpacking, washing, sorting, detecting metal, crushing, floating washing, hot washing, rubbing, rinsing, dehydration, drying and packaging process steps. Technical Features: 1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 100-2000kg/hr. 2.Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop. 3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes. 4. This China Hot Selling Waste PVC Washing Machine can easily wash and recycle waste PVC pipes. Equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed. 5. The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

Be the first person to like this.

Video Player is loading.

Plastic Film Washing Machine l Plastic Scrap Washing Line Plastic/Woven Bag Washing Machine

9 views

Plastic Film Washing Machine l Plastic Scrap Washing Line Plastic/Woven Bag Washing Machine

Industrial Film Printing Packaging Plastic Film Recycling Crushing Washing Line of Wanrooetech is capable of processing a wide range of hard and soft plastic waste, for example, agricultural films, greenhouse films, package films,PE waste film,PP waste film,PVC waste film,industrial film,printed film and etc.

Plastic Film Washing Machine l Plastic Scrap Washing Line Plastic/Woven Bag Washing Machine

Industrial Film Printing Packaging Plastic Film Recycling Crushing Washing Line of Wanrooetech is capable of processing a wide range of hard and soft plastic waste, for example, agricultural films, greenhouse films, package films,PE waste film,PP waste film,PVC waste film,industrial film,printed film and etc.

PP PE plastic washing recycling machine is widely used to washing recycling the used PP/PE plastic soft plastic. Such like shopping bags, packing films, garbage bags, woven bags, non-woven bags and films. This recycling machine can crushing washing and drying the dirty soft plastic into clean film flakes. After plastic film/bag flakes cleaned, you can make them into pellets/granules with next process, which called plastic pelletizing machine. This production line is high automatic operating and low consume, can save labor, save power and save water, easy to maintenance. With advanced design, concepts and technologies to suit different status of waste plastic bags/films. This PP PE plastic recycling machine could layout as “L”, “S” or “U” shape according different workshop.

Features : 1.To crushing washing recycling the used, dirty waste PP PE films/bags, protect the environment, Avoid white pollution. 2.This recycling line is composed of crusher, cold & hot washing system, dewatering, drying, packing system, etc. 3.This PP PE waste plastic crushing, recycling and washing recycling machine line can easily wash and recycle waste PP PE films/bags. Waste and dirty PP PE films/bags can be processed step by step, by this recycling machine. It is special for washing PP PE films/bags. We can help to attach equipment at the end of the washing recycling line so that the completely dry flakes can be collected and packed directly after been washed. 4.The whole production line can designed based on how dirty the PP PE films/bags are, and make sure of the quality of the final products. 5.Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PP PE films/bags to be the PP PE granules material and in order to producing new PP PE products.

Be the first person to like this.

Video Player is loading.

Shrimp Skin Ultrafine Pulverizer Machine Traditional Chinese Medicine Powder Grinding Machine

9 views

Shrimp Skin Ultrafine Pulverizer Machine Traditional Chinese Medicine Powder Grinding Machine

ultrafine pulverizer machine has powerful crushing capabilities and can finely grind food raw materials such as dried shrimps into micron-sized powder.This advantage allows the nutrients in shrimp skin to be fully released and improves the utilization rate and added value of shrimp skin powder.At the same time, the fine crushing process also ensures the uniform particle size of shrimp skin powder, making its subsequent processing and use more convenient.ultrafine pulverizer machine

Technical Features: 1. Fully enclosed structure effectively reduces material loss and improves production efficiency. 2. Adopt advanced energy-saving technology, new high-yield pulse dust removal equipment and silencers to reduce energy consumption and noise pollution. 3. Equipped with a precise fineness adjustment device, which can adjust the finished product arbitrarily within the range of dozens to hundreds of meshes according to user needs. Fineness ensures the stability and controllability of product quality. 4. The use of high-quality wear-resistant materials and precision manufacturing technology improves the wear resistance and stability of the equipment. 5. Equipped with a PLC automatic control system, which can monitor the operating status and crushing effect of the equipment in real time to achieve intelligent control.

Be the first person to like this.

Video Player is loading.

100-2000kg/h Laboratory Milling Machine PET Pulverizer Machine PET-B Grinder Machine

5 views

100-2000kg/h Laboratory Milling Machine PET Pulverizer Machine PET-B Grinder Machine

Our laboratory-style pulverizer can make samples and trials faster and easier. This multi-functional pulverizer can serve a variety of top-level markets that require high-quality sample powders. Almost anything can be tried on this machine, such as engineering resin, rubber, adhesive, pharmaceutical, seasoning and food grade.

Applications: The lab pulverizer is widely used in pharmaceutical, food, chemical. It can be used for making sugar powder , salt powder and crystal material. Spice industry like chili , pepper , pimento,coriander,cumin , cinnamon , cardamom , Star anise, celery seed , , ginger , Licorice ,etc. Grains like rice , chaff , corn , Sweet potato bran , coffee ,etc. Chemical like resin, plastic, sodium hydroxide, calcium hydroxide, ammonia. Sodium chloride, sodium carbonate, copper sulfate, ferric chloride, ferrous chloride, phenolphthalein, methyl orange, litmus.

Advantages: 1.Elimination of outside services for trials. 2.Smallest batch sizes for cost effective test runs. 3.Ambient and Cryogenic ready. 4.Versatile hopper design for inlet/outlet. 5.Small footprint, equipped with casters for easy portability.

Be the first person to like this.

Video Player is loading.

100-2000kg/h Laboratory Milling Machine PET Pulverizer Machine PET-B Grinder Machine

7 views

100-2000kg/h Laboratory Milling Machine PET Pulverizer Machine PET-B Grinder Machine

Our laboratory-style pulverizer can make samples and trials faster and easier. This multi-functional pulverizer can serve a variety of top-level markets that require high-quality sample powders. Almost anything can be tried on this machine, such as engineering resin, rubber, adhesive, pharmaceutical, seasoning and food grade.

Applications: The lab pulverizer is widely used in pharmaceutical, food, chemical. It can be used for making sugar powder , salt powder and crystal material. Spice industry like chili , pepper , pimento,coriander,cumin , cinnamon , cardamom , Star anise, celery seed , , ginger , Licorice ,etc. Grains like rice , chaff , corn , Sweet potato bran , coffee ,etc. Chemical like resin, plastic, sodium hydroxide, calcium hydroxide, ammonia. Sodium chloride, sodium carbonate, copper sulfate, ferric chloride, ferrous chloride, phenolphthalein, methyl orange, litmus.

Advantages: 1.Elimination of outside services for trials. 2.Smallest batch sizes for cost effective test runs. 3.Ambient and Cryogenic ready. 4.Versatile hopper design for inlet/outlet. 5.Small footprint, equipped with casters for easy portability.

Be the first person to like this.

Video Player is loading.

3000-8000kg/h Waste big blue barrel IBC Bucket Plastic Bucket Shredder Crusher Pulverizer Machine

8 views

3000-8000kg/h Waste big blue barrel IBC Bucket Plastic Bucket Shredder Crusher Pulverizer Machine

The PVC pulverizer recycling line contains swing arm single shaft shredder overband belt magnetic separator,plastic crusher,screw feeder,plastic pulverizer machine(4 sets),sew discharge,storage silos,pulse dust collector. Mainly used to recycle PVC flooring,big blue barrel,PVC window profile, the output is 2000-3000kg/h. PVC shredding crushing grinding recycling production line has the characteristics of high output,labor saving,small footprint, and dust-free workshop.

Be the first person to like this.

Video Player is loading.

PE Cryogenic Grinding Miller Machine Liquid Nitrogen Cooling System Plastic PE Grinder Machine

8 views

PE Cryogenic Grinding Miller Machine Liquid Nitrogen Cooling System Plastic PE Grinder Machine

This cryogenic pulverizer system can be used for all kinds of materials which can not be crashed/grinded in normal temperature, widely apply for all kinds of oily food containing sugar, chemical, petrochemical,machinery,shipbuliding, and auto-industry, costume,coating,printing,resin,engineering plastic,rubber, shoe material, thermoplastic material?thermosol, nylon, polyester, PP,PE, thermoplastic-elastomer TPU/TPEE,Nylon material PA11?PA1010?PA12?PA6?PA66?PA610 copolymer nylon, PET, PTFE,PE,EVA, food industry (chilli powder), Chinese and Western Medicinal products's super fineness grinding.

While grinding, the cooling source of cryogenic pulverizer system is forming a closed -circuit circulation system, so the cooling source will be thoroughly used,save energy; and the particle fineness degree rang from 10-700 mesh, even reach micron fineness degree. Apply liquid nitrogen as grinding medium, achieve cryogenic grinding, anti-explosion, anti-oxidation etc effect. In the pulverizing system, the cold source forms a closed cycle system, which makes full use of energy and saves energy. The temperature of the cold source for grinding can be reduced to 196 degrees below zero. According to the brittle point temperature of the material, the temperature can be controlled in the grinding process, and the best grinding temperature can be selected, so as to reduce the energy consumption. The grinding fineness can reach 10-700 meshes, and even reach micron fineness. In addition, liquid nitrogen is used as grinding medium to achieve ultra-low temperature comminution, which can achieve the comprehensive effect of explosion proof and oxidation resistance of materials.

Be the first person to like this.

Video Player is loading.

PNMP-800 PVC Pulverizer Machine PVC Pipe Miller PVC Pipe Grinder Machine PVC Powder Machine

8 views

PNMP-800 PVC Pulverizer Machine PVC Pipe Miller PVC Pipe Grinder Machine PVC Powder Machine

PVC Scrap Recycling Pulverizer Mill Machine is designed by our factory using Germany technology and our own production experience. PVC pulverizer machine is used to grind waste SPC floor?PVC ceiling, PVC pipe, PVC profile, PVC marble sheet into fine powder. The capacity can be from 100-900kg/h.

This PNMP PVC Plastic mill is chiefly designed to grind PVC. The pulverizer uses turbo type blade. The static blade and rotary blade could be adjusted, thus you can get different size of PVC powder with one grinder. High output, low energy consumption and long lifespan attract many customers around the world. It can be used for PVC plastic from PVC pipe/profile/soft sheet/bottle/card from low to moderate hardness PVC. The output of our PNMP pulverizer can reach 100-900kg/h (15-100mesh). The plastic pulverizer machine is mainly composed of electric motor, disc type blade, feeding fan, vibrating sieve, dust removing system, etc. According to the customer's needs, you can choose some accessories, such as converter, vacuum loader, screw loader, magnetic net, metal separator, chiller, pulse dust collector, metering and weighing packaging machine, etc.

This PNMP PVC Plastic mill is chiefly designed to grind PVC. The pulverizer uses turbo type blade. The static blade and rotary blade could be adjusted, thus you can get different size of PVC powder with one grinder. High output, low energy consumption and long lifespan attract many customers around the world. It can be used for PVC plastic from PVC pipe/profile/soft sheet/bottle/card from low to moderate hardness PVC. The output of our PNMP pulverizer can reach 100-900kg/h (15-100mesh).

Be the first person to like this.

Video Player is loading.

PE Cryogenic Grinding Miller Machine Liquid Nitrogen Cooling System Plastic PE Grinder Machine

9 views

PE Cryogenic Grinding Miller Machine Liquid Nitrogen Cooling System Plastic PE Grinder Machine

Liquid nitrogen tank, material solo,machinery grinding machine, draught fan, powder discharging cyclone.

This cryogenic pulverizer system can be used for all kinds of materials which can not be crashed/grinded in normal temperature, widely apply for all kinds of oily food containing sugar, chemical, petrochemical,machinery,shipbuliding, and auto-industry, costume,coating,printing,resin,engineering plastic,rubber, shoe material, thermoplastic material?thermosol, nylon, polyester, PP,PE, thermoplastic-elastomer TPU/TPEE,Nylon material PA11?PA1010?PA12?PA6?PA66?PA610 copolymer nylon, PET, PTFE,PE,EVA, food industry (chilli powder), Chinese and Western Medicinal products's super fineness grinding.

Be the first person to like this.